The advantages of welded custom profiles compared with standard profiles (IPE and HEA)

Welded custom profiles (WCP) are popular in the field of steel construction because of their advantages in certain situations over standard sections such as IPE and HEA.

Welded custom profiles allow greater design flexibility, as they can be tailored-made to meet the specific requirements of a project, which is not possible with standard profiles. This flexibility makes it possible to optimise the dimensions and mechanical properties of beams and columns, reducing the weight and therefore the cost of materials.

WCP made from S355 steel sheets and flat bars can achieve higher mechanical strengths than S275 rolled sections. This increased strength means that fewer cross-sections are required, resulting in savings in materials and reduced transport and handling costs.

The manufacturing costs of welded custom profiles are higher than those of commercial profiles. It is therefore necessary to reserve the use of WCP for situations where large cross-sections are required.

Designing welded custom profiles according to the Eurocodes (specific features of class 4 sections)

The design of WCP according to the Eurocodes, in particular class 4 sections, presents certain particularities that are important to understand. Class 4 sections are thin-walled sections that may be subject to local buckling before they reach their ultimate load-bearing capacity. For this reason, it is essential to take into account the effects of local buckling of the walls in the design of welded custom profiles by carrying out the calculations on the basis of the effective characteristics of the section.

The Eurocodes provide specific methods for the design of class 4 sections. These calculation methods are mainly detailed in part 1-5 of Eurocode 3 (Design of steel structures – Flat plates), more particularly in section 4, which gives the rules for taking into account the effects of plate buckling due to normal stresses exerted in the limit state during compressive or flexural stresses, and section 5, which gives the rules relating to shear buckling in the ultimate limit state.

Another phenomenon not to be neglected is the possible offset eN of the neutral axis of the effective area Aeff with respect to the centre of gravity of the gross section and the resulting additional moment. The calculation of the additional moment is given in part 1-1 of Eurocode 3 in paragraph 6.2.2.5. It is then included in the equations for Class 4 cross-sections subjected to compression, such as the one presented in paragraph 6.2.9.3 :

\[\frac{N_{Ed}}{A_{eff} \cdot f_{y} / \gamma_{M0}} + \frac{M_{y,Ed} + N_{Ed} \cdot e_{Ny}}{W_{eff,y,min} \cdot f_{y} / \gamma_{M0}} + \frac{M_{z,Ed} + N_{Ed} \cdot e_{Nz}}{W_{eff,z,min} \cdot f_{y} / \gamma_{M0}} \le 1\](EN1993-1-1 eq. 6.44)

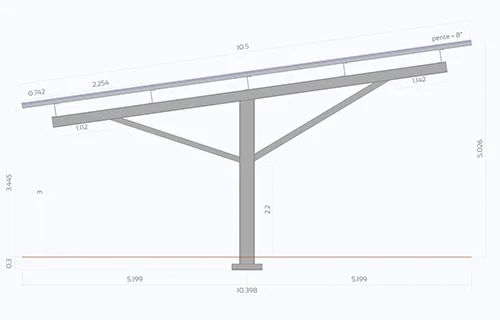

Case study

For this case study, we are using our photovoltaic shelters design software, PV-Shelters, which allows us to choose between standard profiles and welded custom profiles (WCP). We save 40% on material while maintaining equivalent performance. Although the manufacturing cost is higher (€/kg), the use of WCP for the construction of the Carport’s poles is clearly more advantageous.

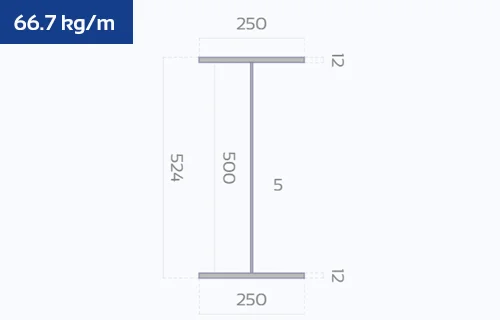

With standard profiles

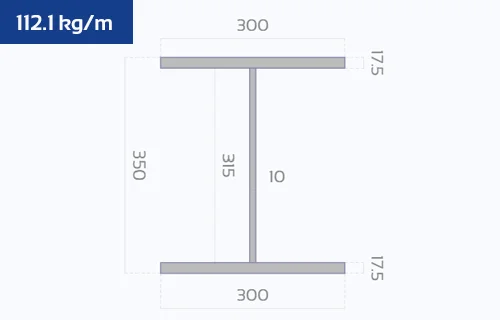

With welded custom profiles